AI-Driven Force Analysis Applying Newton's Second Law to Enterprise Robotics

AI-Driven Force Analysis Applying Newton's Second Law to Enterprise Robotics - Newton's Second Law Fundamentals in Enterprise Robotics

Newton's Second Law forms the bedrock of enterprise robotics, dictating the connection between force, mass, and acceleration. This law essentially translates how different forces applied to an object translate into distinct accelerations, with the object's mass being the key factor. This is invaluable when designing effective robotic systems. By applying the principles of Newton's Second Law, engineers can pinpoint the precise forces needed to achieve specific movements, thereby enhancing the responsiveness and performance of industrial robots. This knowledge also facilitates optimization of control systems, ensuring that robots not only function efficiently but prioritize safety in automated processes. Ultimately, understanding this fundamental law is critical for progress in AI-driven force analysis within the field of enterprise robotics.

Newton's Second Law, that bedrock of physics expressed as F=ma, has a deep impact on the world of enterprise robotics. It guides the creation of algorithms designed to control robotic movements, ensuring safe and efficient interactions with both human operators and the environment. This is particularly important as robots are increasingly tasked with delicate handling and precise manipulation in various industrial settings.

While the law's basic principle is straightforward, its application in the realm of robotics is complex. It applies not only to linear movement but also to rotational dynamics, which means robots must simultaneously account for torque and angular acceleration – a considerable challenge for their control systems. Moreover, friction, a crucial factor in Newton's Second Law, impacts a robot's ability to grasp and manipulate objects, adding to the complexity of designing efficient and powerful systems.

Another key concept is inertia. Robotic joints must be designed to overcome the inertia of robotic arms and other mechanisms during movement without compromising speed or accuracy. The inherent limitations posed by inertia are a recurring challenge for robotics engineers, who employ a variety of innovative approaches to mitigate its impact.

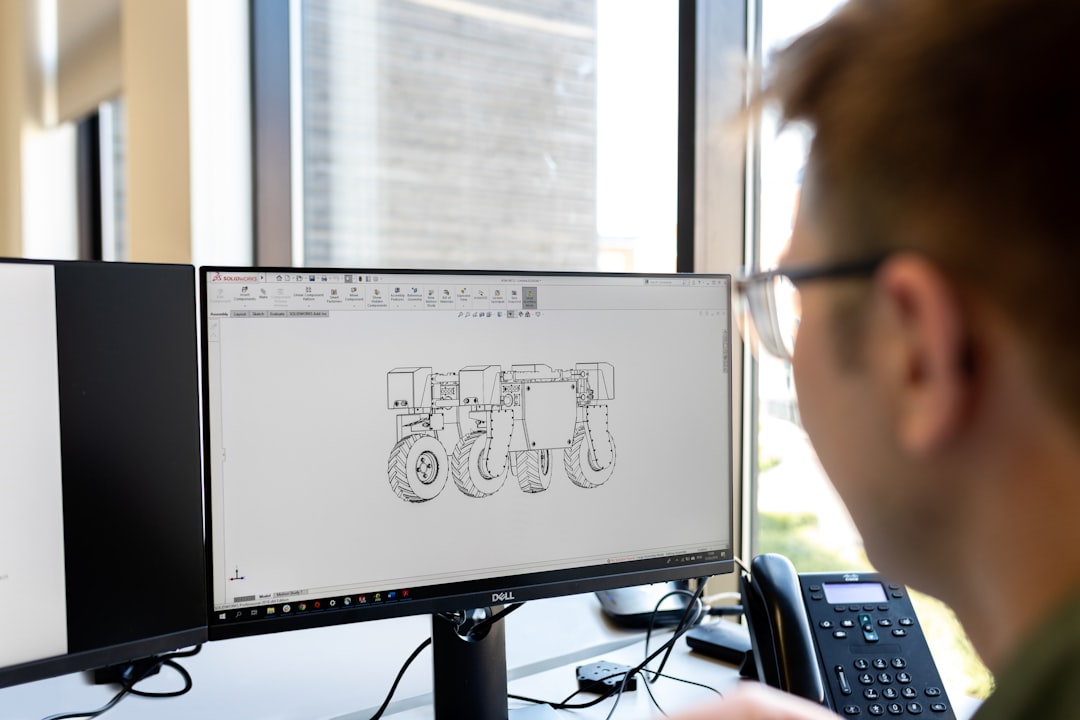

One common practice is simulation. Robotics teams use sophisticated software to predict how robots will behave under varying loads and conditions, allowing them to test and refine designs before constructing physical prototypes. This process helps to avoid costly mistakes and ensures the robots are built to meet the demands of real-world applications.

But the application of Newton's Second Law goes beyond design. In an industrial setting, robots must navigate unpredictable situations. For example, a robot might encounter changes in weight or force requirements due to varying payloads. This necessitates adaptive control strategies that constantly refine the application of Newton's Second Law principles, ensuring robots can adjust to unexpected challenges without compromising efficiency.

This dynamic adjustment is made possible through the integration of sensor technologies. Sensors gather crucial data about acceleration, force, and mass, enabling sophisticated processing that enhances decision-making accuracy for the robot.

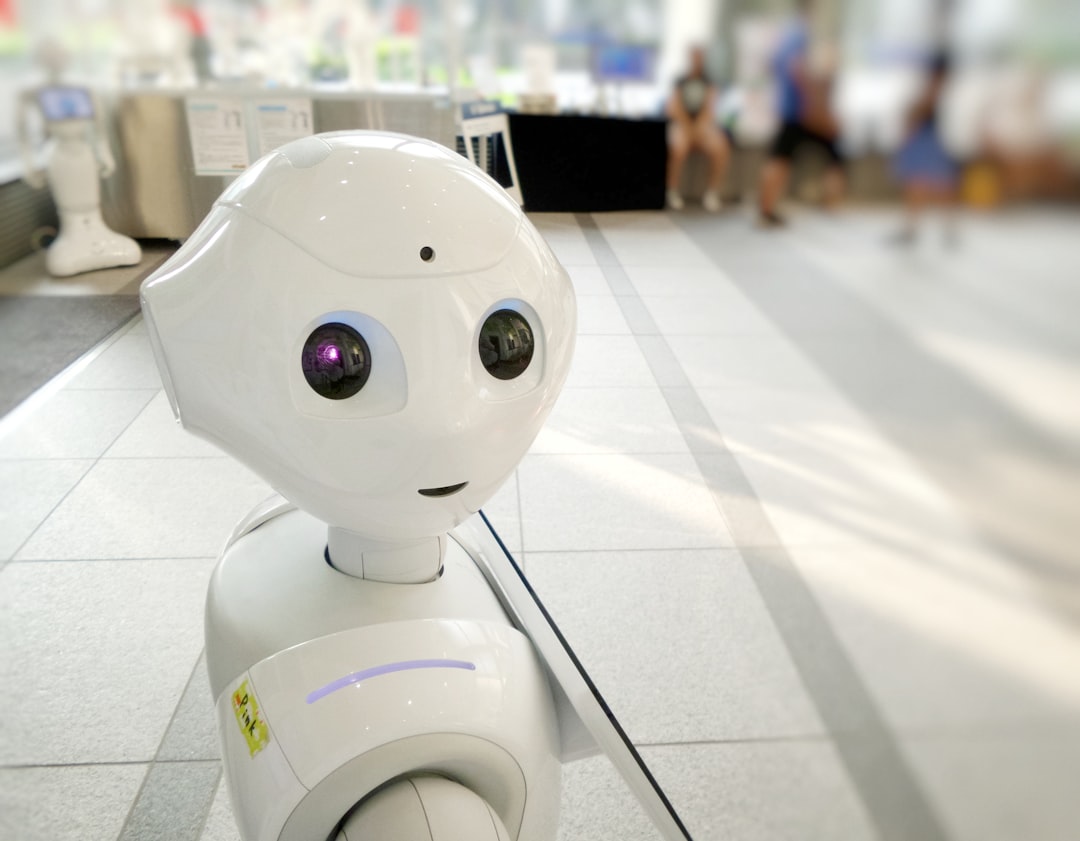

Collaborative robots (cobots), designed to work alongside humans, present a unique application of Newton's Second Law. The forces they exert must be tightly controlled to prevent injury, highlighting the critical role of this law in human-robot interaction.

Beyond the immediate realm of industrial tasks, Newton's Second Law also plays a crucial role in optimizing robotic systems for logistics. By optimizing acceleration and deceleration curves, robotics engineers can minimize energy consumption during transport tasks, underscoring the synergy between physics and operational efficiency.

Newton's Second Law remains a guiding principle for robotics development, inspiring innovation in both theoretical understanding and practical application. As the field continues to evolve, the law will undoubtedly play a central role in developing intelligent robots that interact seamlessly with humans and the world around them.

AI-Driven Force Analysis Applying Newton's Second Law to Enterprise Robotics - AI-Enhanced Dynamic Modeling for Robotic Systems

AI-Enhanced Dynamic Modeling for Robotic Systems takes the established principles of robotics and pushes them further by integrating AI algorithms and real-time data analysis. This approach combines robotic simulations, AI-powered image analysis, and cloud-based digital twin technology. The result is a deeper understanding of robot movement and more effective decision-making within the system. Recent advancements, like Self-Adaptive Robust Attention for Robotics Transformers, demonstrate the increasing complexity and capabilities of AI-enhanced robotics. These systems are able to adjust their control mechanisms even when faced with unpredictable environments. Additionally, the exploration of nonlinear dynamic analysis in the context of soft robotics highlights the need for customized computational techniques to properly model their unique mechanics. With AI's ongoing influence in robotics, the synergy between traditional mechanics and advanced modeling methods is crucial for pushing the limits of robotic capabilities.

AI-enhanced dynamic modeling is revolutionizing how we design and control robotic systems. It's about combining the power of AI with the fundamental laws of physics, specifically Newton's Second Law, to create more sophisticated and adaptable robots. Imagine robots that can anticipate how forces will affect their movements, adjusting their behavior in real-time to handle unpredictable situations.

This is achieved by incorporating machine learning algorithms into the modeling process. These algorithms learn from data collected by advanced sensors, allowing the models to become more accurate over time. They can analyze variables like joint torque and external forces, helping robots react more intelligently to changing loads and environments.

Traditional models often relied on static assumptions, but AI-enhanced models can handle variability in mass and force. This lets us understand how a robot will behave in a much wider range of conditions. We can also delve deeper into the complex interplay between multiple components within a robotic system, thanks to multibody dynamics analysis.

The beauty of AI is that it significantly reduces the computational complexity of dynamic modeling. Simulations that once took hours or days can now be performed in real-time, accelerating the design process. And through the use of advanced neural network architectures, robots can learn from past experiences, refining their control strategies without human intervention.

The impact of AI extends beyond simple linear models. We can now better understand and predict nonlinear behaviors like slipping or bouncing. This means we can anticipate and prevent potential failures that were previously difficult to predict. And by optimizing the interplay of force and speed, AI helps create robots that are more efficient and productive, especially valuable in time-sensitive industries.

While still a developing area, AI-enhanced dynamic modeling is a game-changer for robotics. It allows us to build systems that are not only more intelligent but also safer and more efficient, bringing us closer to a future where robots interact seamlessly with the world around us.

AI-Driven Force Analysis Applying Newton's Second Law to Enterprise Robotics - Machine Learning Integration with Real-Time Motion Data

The integration of machine learning with real-time motion data represents a significant leap forward for enterprise robotics, especially when it comes to AI-driven force analysis. This integration allows robots to analyze forces more accurately by taking into account the constant change of movement. The use of IoT devices enables seamless transmission of motion data, which is essential for making informed decisions in dynamic environments.

Machine learning is helping to overcome the limitations of traditional sensors, creating more reliable data-driven models. This allows us to develop intelligent control systems that can adapt to changing circumstances. AI is revolutionizing motion analysis, making robotics more precise and versatile, both in industrial settings and in human-robot collaboration.

However, the challenges of ensuring reliability and safety in the real world remain significant as these technologies continue to evolve.

Integrating machine learning with real-time motion data in robotics is a promising approach to developing more adaptive and efficient robotic systems. The idea is that by continuously collecting data on a robot's movement, we can train machine learning models to predict how forces will affect the robot's actions and react accordingly.

This approach has the potential to significantly enhance the performance of robots, especially in complex and unpredictable environments. For example, imagine a robot working on a manufacturing assembly line that can adjust its movements in real-time to account for variations in the objects it's handling. This dynamic adaptation could lead to increased speed, accuracy, and overall efficiency in the manufacturing process.

However, there are challenges to consider when integrating machine learning with real-time motion data. One key challenge is computational efficiency. Processing and analyzing vast amounts of data in real-time requires significant computing power, especially as the complexity of the robot's environment and its tasks increase. Additionally, ensuring that the machine learning models are adaptive enough to learn and adjust their control strategies rapidly presents a significant technical hurdle.

There are also ethical considerations to grapple with, especially when it comes to the potential for biases in the training data. As machine learning algorithms learn from the data they are exposed to, it's crucial to carefully select training data and actively monitor for biases to prevent unintended consequences.

Despite the challenges, the integration of machine learning with real-time motion data holds great promise for the future of robotics. As the field continues to evolve, we can expect to see more innovative applications of this technology, leading to robots that are more versatile, efficient, and adaptable than ever before.

AI-Driven Force Analysis Applying Newton's Second Law to Enterprise Robotics - Addressing Real-World Challenges through AI-Robotic Synergy

The combination of artificial intelligence (AI) and robotics is rapidly evolving, opening doors to address various real-world challenges. By integrating sophisticated sensor technologies with AI-powered data analysis, robots are gaining the ability to adapt to complex, dynamic environments and make autonomous decisions. This partnership is driving innovation, enhancing efficiency and productivity in a wide range of industries. However, it's crucial to approach this technological advancement thoughtfully, considering the implications of AI-powered robots in everyday life, particularly when it comes to safety, ethical considerations, and the delicate balance of human-robot collaboration. While machine learning promises significant potential in robotics, it also raises critical challenges that must be acknowledged and addressed to ensure a responsible and effective implementation.

The combination of AI and robotics is opening up exciting possibilities in the way we design and control robots, particularly when it comes to force analysis. We're essentially trying to make robots more like us, able to adapt to a changing environment in real-time, much like a human adjusts their grip on a delicate object. By integrating AI into the control systems, we can analyze data from force sensors and enable robots to react to changes in loads and forces, making them more productive and safer.

Think about it this way, we're moving beyond simple, pre-programmed robots that follow strict instructions. Instead, we're now able to equip robots with the ability to learn and adapt through AI. This means robots can optimize their movements to minimize wear and tear on their components, extending their lifespan and cutting down on maintenance costs.

What's especially intriguing is the application of AI in soft robotics. These robots are made of flexible materials, allowing them to handle objects with more finesse. AI is helping us to model the unique mechanics of these systems, opening the door for delicate tasks that traditional rigid robots would struggle with.

We're also seeing a shift in how we train robots. Simulations that use AI to expose robots to virtual environments allow us to train them more efficiently, reducing the time and resources required for physical training. These simulations could potentially revolutionize how robots are deployed, allowing for faster scaling and greater adaptability across diverse industries.

The power of AI extends beyond simple learning. AI-powered robots can now analyze massive amounts of sensor data in highly specific contexts, leading to more refined applications in fields like manufacturing and logistics. We can even use AI to predict potential failures before they happen, allowing for proactive maintenance and preventing costly downtime.

AI is allowing us to create robots that can function in dynamic environments where traditional automation struggled. Robots can now respond to unexpected changes like faulty machinery or fluctuating workloads, enhancing the robustness of automated systems.

Finally, the integration of AI and IoT devices is fostering a level of interconnectedness within robotic systems. This collaboration between robots enables more synchronized operations and a more cohesive operational framework within smart factories, ultimately pushing the limits of what robots can achieve.

AI-Driven Force Analysis Applying Newton's Second Law to Enterprise Robotics - Explainable AI for Transparency in Robotic Behavior

The drive towards transparency in robotic behavior is pushing the demand for explainable AI (XAI) in enterprise robotics. We're seeing a growing need to understand how these machines make decisions, especially as they become more autonomous and are used in critical industries. There's a real gap in current legal frameworks when it comes to defining the transparency of these algorithmic decision-making processes. Beyond the need for regulatory compliance, XAI is key for building trust with users who interact with these systems. XAI can make the AI's behaviors more understandable and interpretable, ultimately making robotics more widely accepted and useful in complex environments.

Explainable AI (XAI) is becoming increasingly vital for enterprise robotics. It gives us the ability to understand the "why" behind robotic decisions, particularly when dealing with force analysis. This transparency is crucial for trust and safety, especially when robots work alongside humans. We need to be able to see how the robots arrive at their decisions.

But there's a twist. XAI algorithms themselves can get so complex that they become difficult to interpret. It's a bit of a paradox: the more powerful the AI, the harder it can be to understand its logic. This potential for unintended consequences is a key challenge we must address.

Imagine a robot working on a complex task. XAI can help us trace back its actions to specific data inputs or decision-making logic. This makes debugging much faster and more efficient.

XAI can also visualize how force is distributed across different joints in a robot. This helps engineers identify stress points that might cause failures, leading to improved designs.

With XAI, we can even begin to predict robotic behavior. It can help us model and simulate how robots will react under different force conditions, making them more efficient. But the rapidly growing complexity of AI algorithms makes this task more challenging.

As regulations surrounding AI and automation evolve, explainable AI will be crucial for compliance. We need to ensure that robotic behaviors are transparent and can be easily documented.

XAI can also be used to reduce the cognitive load on human operators. By understanding the logic behind robotic decisions, operators can focus on strategic tasks rather than constantly trying to figure out what the robot is doing.

The potential of explainable AI is huge. It can provide real-time feedback on robotic operations, allowing engineers to adjust parameters instantly. It can even help us predict when a robot's parts are going to fail, leading to better maintenance planning and less downtime.

XAI is opening up fascinating new possibilities for robotics. It's about making complex AI systems more understandable and helping us build robots that are more intelligent, reliable, and safe.

AI-Driven Force Analysis Applying Newton's Second Law to Enterprise Robotics - Force Analysis Simulations Improving Robotic Algorithm Development

Force analysis simulations are becoming an essential tool for refining robotic algorithms. By incorporating AI into these simulations, we're pushing robots to become more adaptable and efficient. This is achieved by training robots to optimize grasping techniques based on things like object shape and weight, making them better equipped to handle complex tasks. These simulations also allow robots to dynamically adjust the force needed for manipulating objects, which is crucial for responding to unexpected changes in their environment. There's a lot of excitement about using AI-powered virtual sensors and reinforcement learning to further improve how robots interact with their surroundings. This promises a future where robots can operate more sophisticatedly and reliably in various industries. However, the complexities of these technologies and the need for robust adaptive control strategies shouldn't be overlooked. Ensuring safe and reliable robotic operations in real-world applications remains a significant challenge.

Force analysis simulations are pushing the boundaries of robotic algorithm development, going beyond simple static models to create virtual worlds where robots can be tested and honed for real-world challenges. These simulations are essentially digital proving grounds where we can see how robots will interact with their environment and how their movements will be affected by various forces.

The power of these simulations lies in their ability to create highly detailed 3D models of robotic interactions. This allows us to see and predict how the robot will behave before it's even built, making for a more efficient design process and significantly reducing costs associated with building and testing prototypes. For instance, we can predict how a robot's movement will be affected by changes in weight or the interaction with different materials.

Beyond just understanding how a robot will behave, these simulations allow us to predict potential mechanical failures and fatigue, ensuring proactive maintenance and ultimately increasing the lifespan of robots. We can also test different scenarios, including those involving multiple robots working together, optimizing their movements for tasks that require coordination and precision.

The integration of real-time data feedback in these simulations further enhances their value. By analyzing data collected by sensors, the robots can adjust their performance in real-time, much like a human would adapt their grip when lifting a delicate object. This level of adaptability is crucial in dynamic environments where robots may encounter unexpected changes in their task or environment.

While simulations can be incredibly valuable, it's important to acknowledge their limitations. We must also address the potential for biases in the data used to train these simulation models, as they can lead to unexpected and potentially harmful outcomes in the real world. Despite these challenges, force analysis simulations are becoming increasingly crucial in the development of robotic systems. They are driving the development of more adaptable, intelligent, and robust robots, paving the way for more efficient and productive automation in various industries.

More Posts from aitutorialmaker.com:

- →Unveiling the AI-Powered Approach to Recognizing Equivalent Fractions

- →AI-Powered Analysis Reveals Hidden Symmetry Patterns in Complex Quadrilateral Recognition Systems

- →How AI Models Apply Compound Inequalities to Optimize Enterprise Resource Allocation

- →Unveiling the Mechanics How AI Can Model Elastic Potential Energy in Materials

- →Demystifying Weight Conversion The Precise Relationship Between Pounds and Ounces in 2024

- →Demystifying Chain Rule Differentiation A Visual Approach with Python Implementations