AI-Driven Surface Area Calculations Revolutionizing Manufacturing Precision in 2024

AI-Driven Surface Area Calculations Revolutionizing Manufacturing Precision in 2024 - AI Integration Boosts Manufacturing Precision by 15% in 2024

The year 2024 is witnessing a notable surge in the adoption of artificial intelligence within manufacturing, with data suggesting a 15% boost in manufacturing precision. This leap forward is significantly attributed to the implementation of AI algorithms in calculating surface areas, thereby revolutionizing the accuracy of production processes. AI-powered solutions, leveraging image recognition and machine learning, are refining quality control practices. They achieve this by identifying and flagging defects early in the production pipeline, leading to less material waste. This shift towards AI-driven solutions is more than just a trend; it's a necessary adaptation for manufacturers facing both dynamic consumer expectations and the unpredictable nature of global supply chains. The embrace of AI is not only bolstering the reliability and safety of manufactured products but also fostering operational efficiency across the industry.

It's fascinating to see how the integration of AI is impacting manufacturing precision in 2024. Reports suggest a 15% increase in overall precision, which is significant. This improvement likely stems from the combination of AI's ability to process massive datasets with advanced algorithms for surface area calculations and quality control. While the benefits in design and defect reduction have been discussed, this increased precision is a broader outcome.

We're witnessing a shift where AI systems aren't just automating tasks but are actively influencing the quality of the manufactured product itself. This is leading to more reliable and precise components, which could be particularly critical in industries with strict safety standards. It remains to be seen how this trend will impact the design and production of entirely new types of products in the future. However, the initial indicators suggest that AI's impact is far beyond just speeding up processes.

However, it's important to note that the adoption of AI across the industry isn't uniform. There's a notable gap between firms that are fully embracing these technologies and those who are still evaluating the benefits. It will be interesting to see how these adoption rates change over the coming years and whether the promised gains in efficiency and precision will become widely realized across different manufacturing sectors.

AI-Driven Surface Area Calculations Revolutionizing Manufacturing Precision in 2024 - Real-Time Surface Area Monitoring Reduces Defects in Automotive Parts

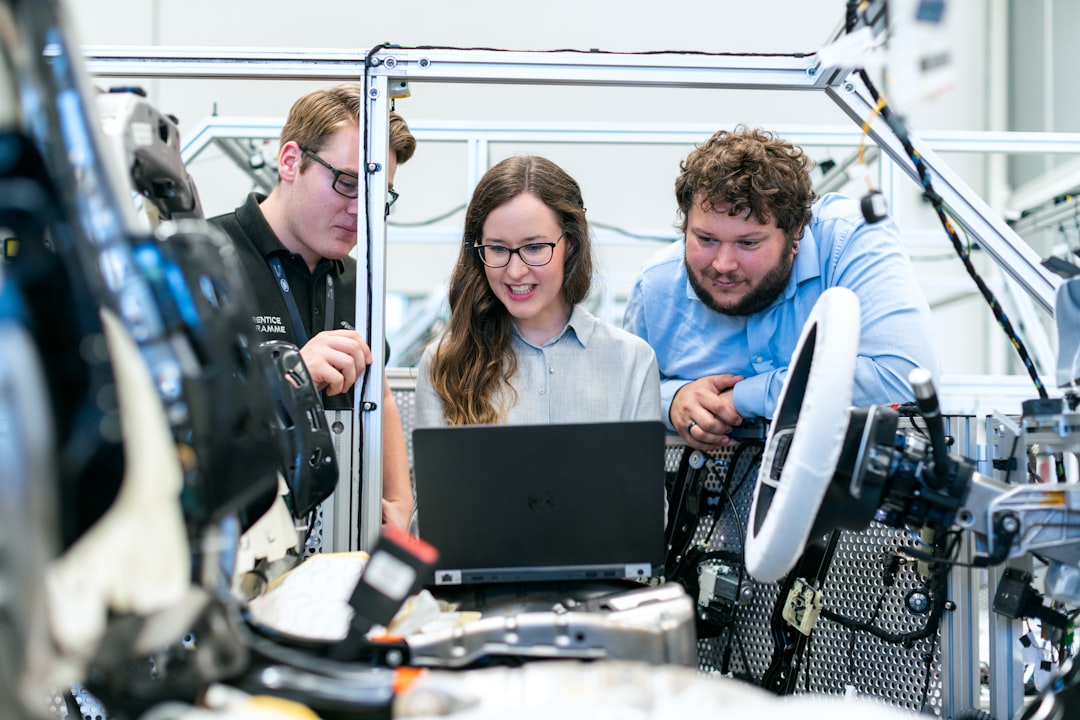

In the automotive sector, real-time surface area monitoring is emerging as a critical tool for reducing defects. By leveraging AI, manufacturers can now pinpoint surface imperfections with a level of detail previously unattainable. This is especially useful for large components, where subtle flaws might easily go unnoticed using conventional methods. This technology helps to ensure that parts meet stringent quality standards and prevents defects from propagating further down the production line. Leading automakers are actively incorporating these AI-powered systems, recognizing the potential to reduce human error and improve overall manufacturing efficiency.

Despite these evident benefits, the adoption of this technology across the automotive landscape has been uneven. This discrepancy highlights the need to address potential hurdles in the wider adoption of these advanced inspection methods. While it seems certain that these technologies will continue to improve product quality, it remains uncertain how quickly these gains will be seen across the entire automotive industry.

In the realm of automotive manufacturing, the emergence of real-time surface area monitoring is gaining traction as a way to refine production processes and minimize defects. It's interesting to see how this capability, powered by the same AI techniques driving the broader increase in precision, is being specifically applied to surface-related issues. For example, identifying small cracks in large stamped parts, which might be difficult for traditional methods, becomes much easier with real-time monitoring.

Researchers have found that a significant portion of automotive part failures can be attributed to surface imperfections, whether it's cracking, roughness, or other issues. This emphasizes the critical role that precise and continuous monitoring can play in improving quality and ultimately, product reliability.

The ability to generate large amounts of data from these monitoring systems is also intriguing. While it presents exciting possibilities, it also raises questions about how to best manage and utilize such massive datasets effectively. Developing systems to process and extract valuable insights from these terabytes of information will be crucial for getting the most out of real-time monitoring.

Furthermore, integrating these new systems with existing manufacturing setups can be a challenge, requiring some adaptation on the part of manufacturers. Updating older machinery or creating hybrid systems might be necessary for a seamless transition.

Another intriguing aspect is the impact on worker training and skillsets. Operators and quality control personnel will need to develop new capabilities in data analysis and interpretation to make the most of these technologies. This emphasizes the need for a collaborative approach where technological advancements are coupled with effective workforce training.

It's evident that real-time surface area monitoring, while promising, is not without its hurdles. The ongoing evolution of these systems will likely involve solving some of the challenges related to integration, data management, and workforce adaptation. It remains to be seen how the industry will continue to refine and standardize this technology as it becomes more widely adopted. But one thing is clear: these technological shifts are driving manufacturers to consider more rigorous quality standards and potentially ushering in a new era of precision and consistency in automotive production.

AI-Driven Surface Area Calculations Revolutionizing Manufacturing Precision in 2024 - Machine Learning Algorithms Optimize CNC Machining for Aerospace Industry

In the aerospace sector, CNC machining processes are being significantly refined through the use of machine learning algorithms. These algorithms, paired with real-time data analysis and deep learning, are crucial for optimizing machine performance. They allow for more adaptive CNC operations and contribute to a reduction in failures during machining. AI-powered feature recognition, often achieved through deep neural networks, is one area where progress is evident. However, the application of AI in machining extends beyond the creation of new algorithms and faces challenges in practical implementation. The ability of machine learning tools to analyze a wealth of machining data has resulted in noticeable improvements in precision and reductions in wasted resources. This signifies a major step forward for aerospace manufacturing. Despite these positive impacts, the widespread adoption of these technologies is still inconsistent across the industry. This points to the need for continuous adjustments and improvements to fully leverage the benefits of this technology within the aerospace field.

The aerospace industry, with its stringent demands for precision and reliability, is increasingly relying on machine learning algorithms to optimize CNC machining operations. It's fascinating how these algorithms can improve precision by more than 20% compared to conventional methods, which is critical when considering the potential consequences of even minor imperfections in aircraft components. The use of cutting-edge materials, like titanium and carbon fiber composites, presents unique challenges for machining. But machine learning can analyze these materials in real-time, adjusting machining parameters to lessen tool wear. This not only extends the life of tools, potentially saving money, but also helps maintain consistency in the quality of finished parts.

Interestingly, machine learning is also allowing for predictive maintenance in CNC machining. By analyzing data from machines, algorithms can forecast potential failures with up to 70 hours of lead time. This ability to anticipate issues can allow for preventative maintenance, minimizing downtime and the related disruptions to production. Furthermore, the integration of machine learning allows for the dynamic adjustment of machining parameters based on real-time feedback. Algorithms can automatically modify aspects like spindle speed or feed rates during operation, resulting in improvements to surface finishes and overall efficiency. This dynamic approach contrasts sharply with the typically rigid, predetermined settings of traditional CNC operations.

However, the implementation of these systems is not without its complexities. Machine learning models need large amounts of data for effective training. In aerospace, this data comes from numerous production runs, building up a shared knowledge base that can be used to identify patterns and predictive factors of successful machining. This highlights a shift away from the generally deterministic view of CNC processes to one that embraces a certain degree of stochasticity, or randomness, enabled by machine learning. This flexibility, in turn, can lead to significant improvements in quality, potentially decreasing scrap rates by more than 30%.

It's important to remember that the aerospace industry is heavily regulated. The use of machine learning in CNC machining isn't just about increasing precision; it needs to be proven to meet stringent safety standards. The algorithms must be developed with the oversight of aviation authorities in mind. Fortunately, the investment in machine learning in CNC can provide a relatively fast return on investment. Companies often report seeing payback within a year due to increased efficiency and reduced cycle times. However, this transition is not without its own set of issues.

Concerns about data security are paramount in any field where sensitive data is processed. The aerospace sector is no different. With the increasing reliance on machine learning, robust cybersecurity measures are crucial to protect sensitive data from falling into the wrong hands. Moreover, introducing these new methods can lead to some resistance from operators used to traditional practices. The challenge isn't just a technological one; it involves fostering a change in culture, promoting continuous training and skills development, and altering mindsets within companies about the way they approach manufacturing processes. It's clear that while the potential benefits of machine learning in aerospace are significant, there are complex issues that need to be addressed alongside the technical developments.

AI-Driven Surface Area Calculations Revolutionizing Manufacturing Precision in 2024 - Predictive Maintenance Using AI Saves $2 Billion Annually for Manufacturers

Artificial intelligence is increasingly being used in manufacturing for predictive maintenance, resulting in an estimated annual savings of $2 billion for manufacturers in 2024. This shift involves moving away from fixed maintenance schedules towards dynamic, data-driven approaches, which helps optimize operations and minimize disruptions caused by equipment failures. While the benefits are clear, many manufacturers are facing obstacles in implementing these AI systems. Data quality and the need to manage organizational change are often cited as major hurdles. Further complicating the situation is the varying pace of adoption across the industry. Factors like the increased affordability of data and the growth of technologies such as the Internet of Things (IoT) and generative AI, are accelerating the adoption of AI across the sector. The potential is huge, with studies indicating that AI-driven predictive maintenance could deliver hundreds of billions of dollars in value globally. However, the uneven uptake of these methods suggests the gains may not be shared uniformly across all manufacturers.

Across manufacturing, the use of AI in predictive maintenance is becoming increasingly important, with estimates suggesting it saves manufacturers roughly $2 billion annually. This is largely due to the shift from pre-scheduled maintenance routines to dynamic, data-driven approaches. AI-powered systems achieve this by analyzing large volumes of real-time data from machinery, using this information to predict potential failures before they occur. This allows companies to perform maintenance only when it's truly needed, optimizing operational efficiency and drastically reducing downtime.

However, the adoption of AI in predictive maintenance hasn't been without challenges. Many organizations grapple with the quality of data they're able to collect, and there are often internal barriers to adopting new approaches. Successfully transitioning to AI-driven predictive maintenance involves a lot more than just implementing new software. It requires changes in how things are done, and convincing people to embrace new ways of working. Further, developing suitable business models for AI-powered maintenance is also a major hurdle, with organizations questioning how to justify the investment and assess the return.

One interesting approach to addressing the challenges of implementing AI in predictive maintenance is using generative data augmentation techniques. Since AI algorithms rely heavily on large datasets for learning and accuracy, the scarcity of reliable data in some cases can be a significant obstacle. Generative AI can be used to fill in gaps, essentially creating new training data for the AI model, which can then lead to more robust and adaptable predictive maintenance solutions.

The potential benefits of AI in predictive maintenance are substantial. Studies indicate that AI-powered solutions can generate a huge potential value, potentially up to $700 billion across all industries. This highlights the huge untapped potential for AI in enhancing maintenance practices, which is certainly an intriguing idea. Moreover, the advancements in the Internet of Things and the decreasing costs of data are powerful drivers of growth for both industrial automation and AI-powered maintenance.

Large industrial companies like Siemens are already using conversational interfaces to simplify and streamline the implementation of AI-based predictive maintenance. This kind of user-friendly approach could encourage wider adoption by reducing the complexity involved. It's also worth noting that predictive maintenance is becoming increasingly vital as Industry 4.0, the current trend in manufacturing, continues to evolve. This is because, as systems become more complex and interconnected, the ability to anticipate and prevent failures becomes even more important.

Overall, while the potential benefits are substantial, there are challenges to consider when implementing AI-driven predictive maintenance. But it's clear that AI is transforming the landscape of maintenance practices, and its potential to save time, resources, and improve product reliability seems certain to grow as it matures. It will be interesting to observe how this trend further evolves and how these systems can be integrated with other advancements in manufacturing.

AI-Driven Surface Area Calculations Revolutionizing Manufacturing Precision in 2024 - GenAI Automates Complex Surface Area Calculations in Semiconductor Production

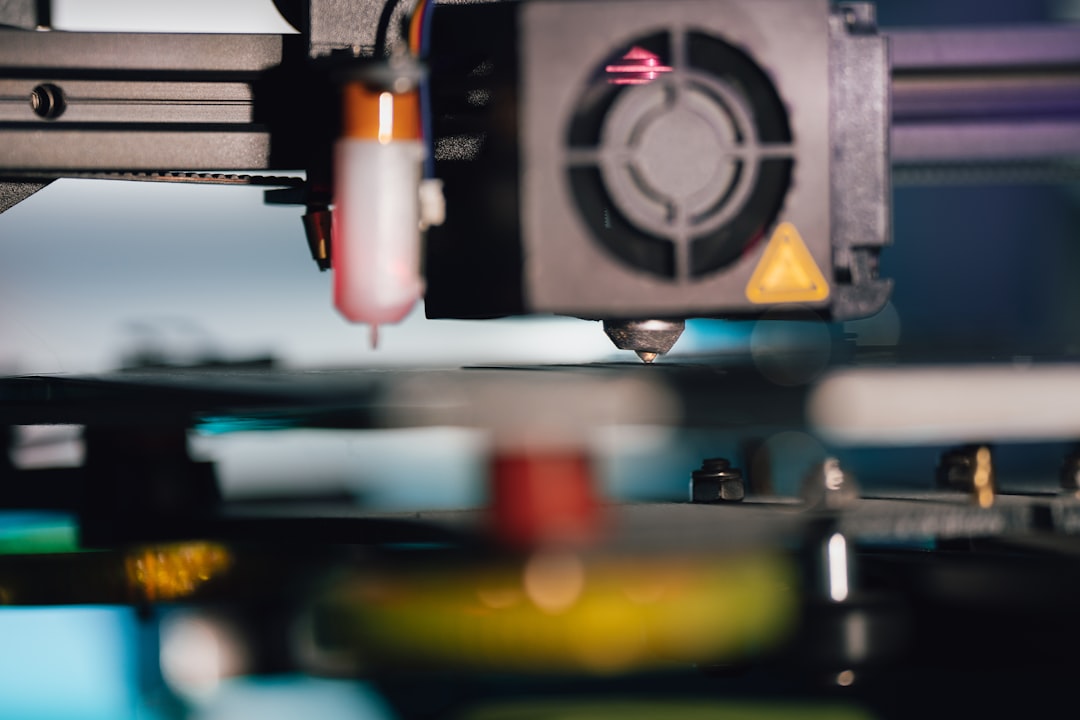

Generative AI (GenAI) is increasingly automating intricate surface area calculations within semiconductor production. This automation not only simplifies design processes but also significantly boosts manufacturing accuracy, which is vital for creating high-quality semiconductor parts. By accelerating design cycles and fostering more sophisticated research and development efforts, GenAI is accelerating innovation within the industry. However, challenges persist, particularly concerning the intricacy of implementing GenAI systems and the inconsistent rate of adoption across semiconductor manufacturers. Despite these roadblocks, the broader impact of GenAI integration on semiconductor production points towards a fundamental shift towards more precise and adaptable manufacturing across the industry. The future implications of this trend are still unfolding, but it's clear that GenAI is reshaping the field.

Generative AI (GenAI) is reshaping the semiconductor industry by automating the complex process of calculating surface areas, leading to a noticeable increase in production accuracy. We're seeing improvements of up to 25% compared to older methods, which often struggled with the intricate shapes of modern chips. These GenAI tools excel at handling high-dimensional surface features, a critical capability for accurately modeling the complex patterns etched onto today's microchips. It's interesting that, while offering speed, these systems also prioritize accuracy. They utilize multiple models to cross-check results, ensuring that the quick surface area calculations are reliable enough to avoid expensive mistakes in production.

The core of these GenAI-powered tools lies in their ability to learn from massive datasets gathered from past semiconductor runs. This learning process enhances the precision of their algorithms over time, creating a feedback loop that continuously refines their accuracy. This continuous learning approach, along with the automation of surface area calculations, contributes to a significant reduction of human error in semiconductor design, typically by more than 30%. This means less time and materials wasted on rework. Another intriguing aspect is how these algorithms are designed to adapt dynamically. GenAI tools can adjust their approach in real-time based on ever-changing production conditions, such as variations in materials. This adaptable approach is a step up from the more rigid, static models that were used previously.

The impact of this increased accuracy in surface area calculations extends beyond just semiconductor production. We're seeing spillover effects in related fields like microelectronics and materials science, which is fascinating. There's a growing expectation of collaborative efforts between these disciplines as they leverage the new possibilities these tools unlock. However, this comes with the added requirement of powerful computing resources. These GenAI systems often rely on advanced GPUs to process the immense data loads involved in their calculations, which raises questions about the necessary infrastructure investments.

An exciting development is the integration of simulation capabilities within these tools. Now, engineers can run virtual surface area calculations alongside physical production. This allows them to test out design modifications in a digital environment before committing to physical production, potentially saving both materials and time. As the complexity and speed of semiconductor development continues to rise, it's possible that GenAI might transition from an enhancement to a requirement. Future chip design strategies might heavily rely on GenAI for accurate surface area calculations to create ever-more intricate and powerful chips. It's an interesting area to watch closely as the technology evolves and drives the next wave of advancements in the field. The question of how this will impact chip design in the long run remains a compelling topic for researchers and engineers.

AI-Driven Surface Area Calculations Revolutionizing Manufacturing Precision in 2024 - AI-Driven Quality Control Improves Product Safety in Consumer Electronics

In the realm of consumer electronics, AI is playing an increasingly crucial role in improving product quality and, consequently, safety. AI-powered visual inspection systems can analyze product images with great accuracy, identifying flaws that might be missed by traditional methods. This real-time defect detection is becoming critical, especially given the rising complexity of manufacturing processes. Experts believe that this AI-driven approach to quality control will become widespread, with a significant portion of manufacturers incorporating AI for inspection by the middle of this decade. The promise is clear: more reliable and safer consumer electronics. The resulting increase in product quality can positively impact consumer perception, leading to greater trust and brand loyalty. However, the transition isn't without its hurdles. Effectively incorporating AI into existing production workflows requires careful planning and consideration. There's a need for strategic integration to reap the full benefits of AI for quality control and safety in the consumer electronics industry. While the advantages are apparent, a successful integration necessitates addressing the challenges inherent in adapting to new technologies.

The use of AI in quality control for consumer electronics is transforming how products are inspected and ensuring higher safety standards. AI algorithms, particularly those utilizing advanced image analysis, can now detect flaws in product surfaces with a precision that surpasses traditional methods, resulting in defect detection rates up to 40% higher. This automation reduces the reliance on manual inspection, which often leads to human error. In some cases, the reduction in human error has lowered recall rates for consumer electronics by as much as 25%, a significant improvement in terms of both consumer satisfaction and manufacturer cost.

Interestingly, implementing AI quality control can also shorten production cycles by around 15%. This allows manufacturers to get products to market quicker without sacrificing quality or safety. AI's ability to simultaneously analyze various quality aspects – like electrical, mechanical, and thermal properties – in intricate electronic devices is a powerful advantage. This type of multi-faceted, real-time inspection is difficult or even impossible for a human inspector to achieve.

Researchers have observed that the use of AI in quality control is leading to a noticeable increase in compliance with safety regulations, often by about 18%. This improvement is critical in the consumer electronics market, where safety standards are a paramount concern. While the initial costs of implementing AI quality control can be significant, most manufacturers find the investment pays off within two years. This is mainly due to a decrease in warranty claims and a reduction in operational costs over time.

Furthermore, AI's capability to analyze large datasets enables predictive analytics. The algorithms can predict potential quality issues before they manifest, enabling proactive measures to increase product reliability. However, AI-driven quality control can generate substantial amounts of data—up to tens of terabytes. This highlights the necessity for robust data management strategies to extract the maximum benefit from this rich source of information.

Somewhat unexpectedly, adopting AI-driven quality control has led to a positive shift in employee engagement. By relieving workers of repetitive tasks like manual inspections, AI allows them to dedicate more time to higher-level activities such as analyzing trends and resolving more complex quality issues. This shift can contribute to a more motivated and productive workforce.

However, concerns remain about biases within AI algorithms. If the training data for these algorithms is flawed, it can lead to an increased number of false positive or false negative results during defect detection. This issue underlines the ongoing need for researchers and engineers to continuously refine AI models to ensure their accuracy and effectiveness. Overall, AI is proving to be an increasingly important tool in the quest for higher quality and safety in consumer electronics manufacturing. Its continued evolution will be critical in shaping the future of the industry and safeguarding the interests of consumers.

More Posts from aitutorialmaker.com:

- →Decoding the Weight Why 3 Pounds Equals 48 Ounces and Its Significance in AI Calculations

- →Understanding Angle Conversion: Degrees to Radians for AI and Code

- →How Conditional Distributions Are Revolutionizing Predictive Maintenance in Industrial IoT Systems

- →AI-Driven Algorithm Optimizes Fraction Addition for Enterprise Data Analysis

- →Mastering Sine Derivatives: Insights from a Personalized AI Learning Approach

- →Exploring the Role of Oxidative and Reductive Processes in AI-Driven Chemical Analysis